Surface roughness:>1.6

Detectable crack size:3mm*0.01mm*0.1mm(length*width*depth)

Detectable hole size:¢0.7mm*0.7mm( diameter *depth )

Detection rhythm:5 seconds per beat

The camshaft is a component of the piston engine. Its role is to control the opening and closing of the valve. Although the speed of the camshaft is half of the crankshaft in a four-stroke engine (the speed of the camshaft is the same as that of the crankshaft in a two-stroke engine), usually its speed is still high and it needs to withstand a lot of torque, so the design is correct. Camshafts are highly demanding in strength and support, and are generally made of high-quality alloy steel or alloy steel. Since the law of valve motion is related to the power and running characteristics of an engine, the camshaft design plays an important role in the design process of the engine.

Eddy current testing is a method of detecting the surface defects of components and metal materials by using the principle of electromagnetic induction. The detection method is to detect the coil and its classification and structure of the detecting coil.

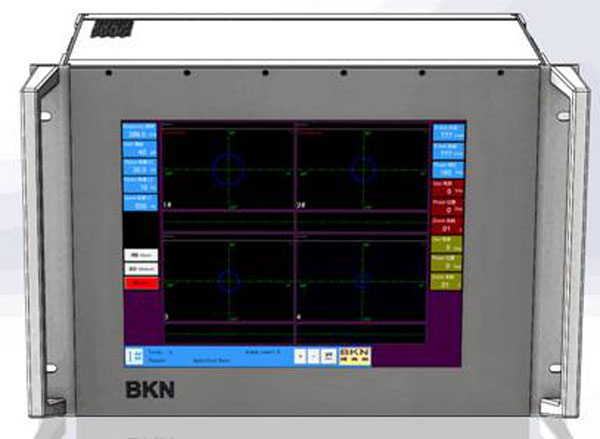

Product front

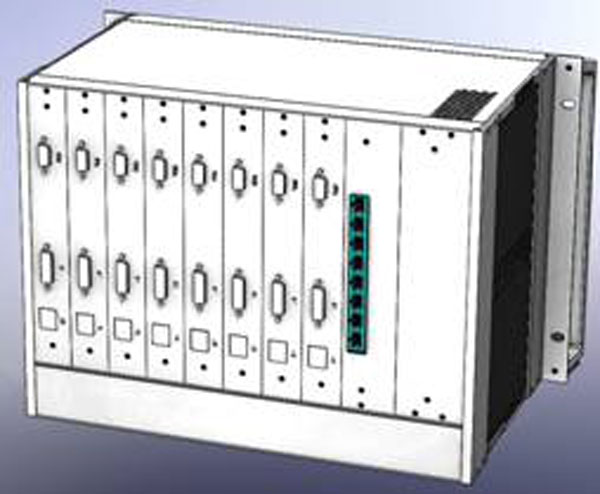

The reverse side of the product

Detection channel | Four channels |

Detection Speed | 12 pieces/min |

Frequency range | 10Hz~10MHz |

Gain | 0~99dB,step size 0.1dB |

Advanced filtering | have |

High pass | 0.1Hz~650Hz |

Low pass | 1Hz~10000Hz |

Phase rotation | 0-360 °step 1 ° |

Synchronized alarm output controlled the internal and external clock |

High precision end and an end to tail signal removal |

High precision real-time and delayed alarm output |

Fast digital /analog electronic balance |

Memory track delay blanking function |

Real-time impedance plane function |

The instrument can be matched to any probe |

The remote automatic control system |

Computer full digital parameter adjustment |

Non-equal amplitude phase/amplitude alarm domain |

Leave us Message: