BKN welded pipe eddy current testing machine is used for inline and offline inspection of high-frequency electrical resistance welded steel pipes. It has a high sensitivity to welding defects such as poor welding, low welding, missing welding, virtual welding, holes, inclusions, cracks...

If there will be defected item, then there will be a light signal + sound signal + spray.

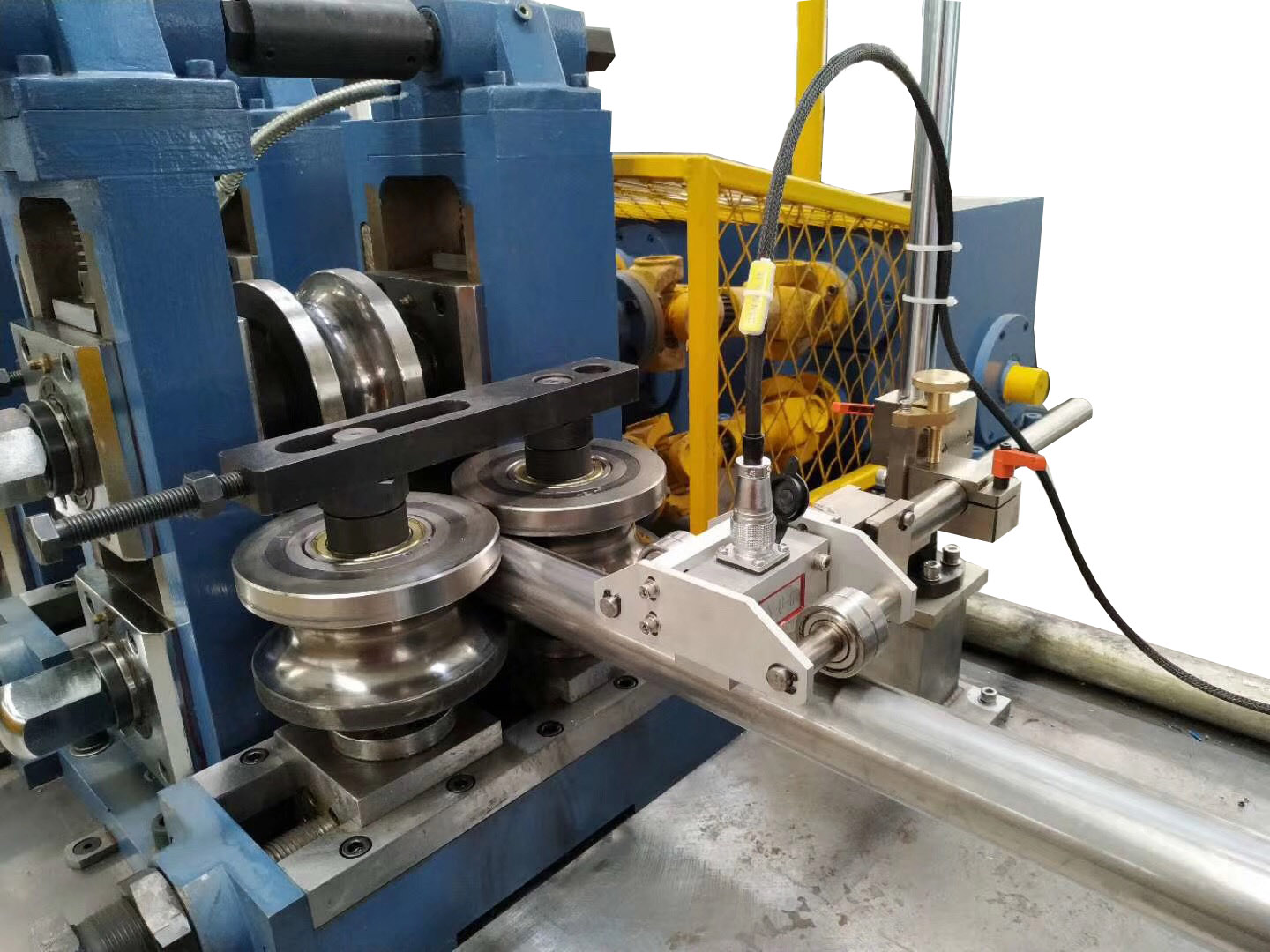

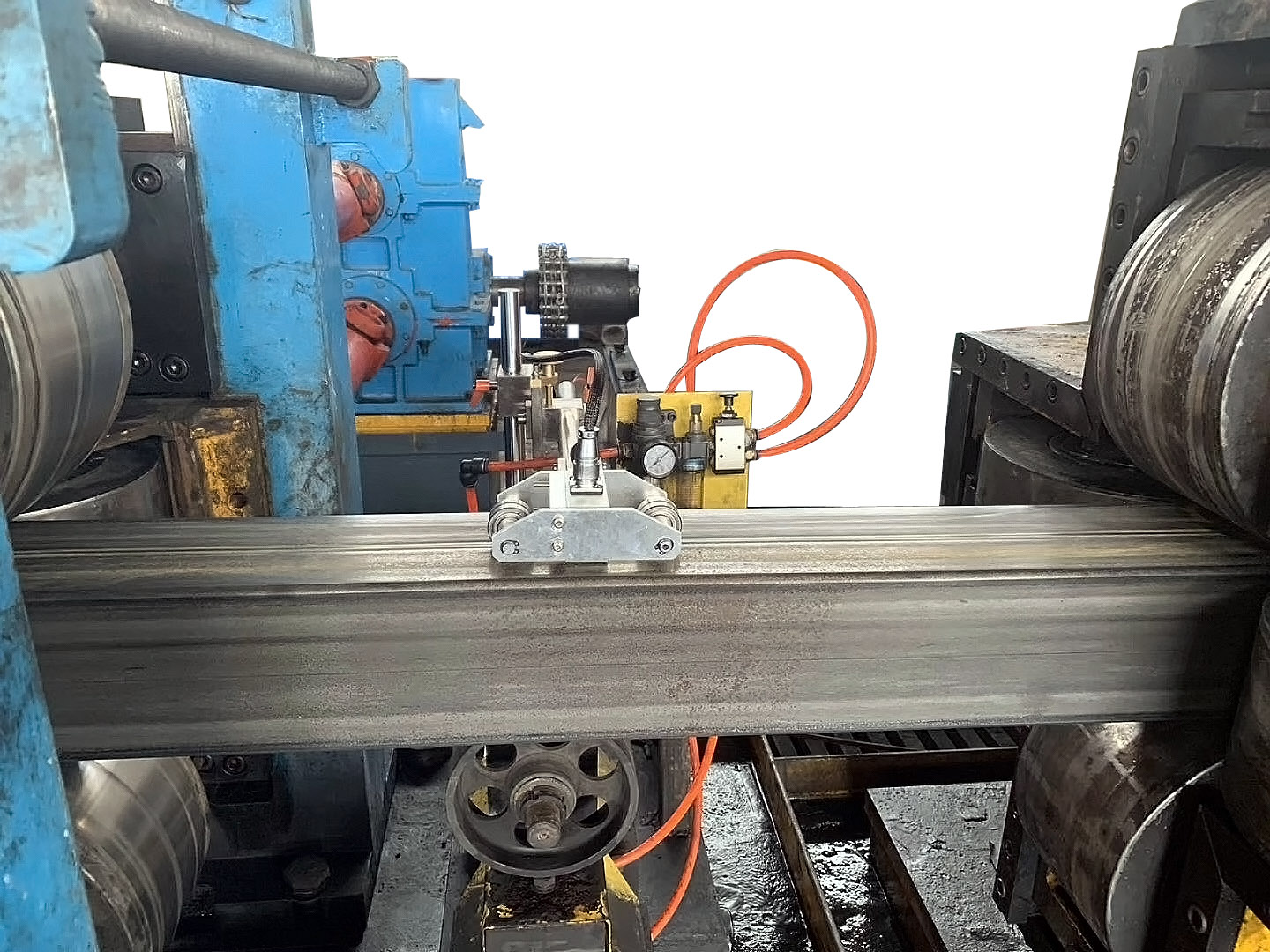

If only detect the welded seam, we suggest using the saddle-shaped probe. One probe can cover a wide range of diameters. Align the center of the saddle probe to the position of the weld. Then we can start detecting.

If detecting the full body of the pipe, then we should use the encircling coil. For every 1mm change in the outer diameter of the pipe, then an encircling coil and a pair of guide bushes should be changed.

If you are looking for a reliable eddy current machine for sale, BKN offers advanced solutions to ensure precision, efficiency, and dependable quality control.

Leave us Message: