ECT Eddy current testing used by Eddy current equipment for sale is a non-contact testing method, which mainly uses the electromagnetic field and electromagnetic induction between metals to detect. It is one of the NDT non-destructive testing methods in the industry.

We can use different coils according to the shape of the specimen and the purpose of detection. There are usually three types of coils: through a coil, probe coil and insert coil. It is mainly used for the rapid detection of metal pipes, rods and wires on production lines, and for the detection of large quantities of parts such as bearing steel balls, valves, etc.

Eddy current testing is a non-destructive testing technique in which an alternating current electromagnetic coil induces eddy currents on the surface of a metal member. It is suitable

LEARN MORE >

The eddy current testing (BKNET-101) is a fully automatic inspection machine that uses large-scale imported integrated circuits combined with advanced eddy current technology, photoelectric technology...

LEARN MORE >

Welded pipe eddy current testing is the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossless.

LEARN MORE >

Using eddy current signal processing method and high performance DSP algorithm, the detection ability of micro-crack is as high as 0.05mm deep crack. Using computer digital technology and...

LEARN MORE >

The aluminum tube is a type of non-ferrous metal which may have one or more closed through holes which are thick and uniform in cross section. It is widely used in aviation, electrical

LEARN MORE >

Product Performance Testing Standard:GB/T 11260-2008 round steel eddy current testing method, GB/T 7735-2004 steel tube eddy Current testing method Longitudinal artificial injury:0.10(depth)×0.10

LEARN MORE >

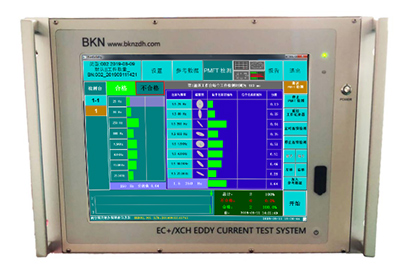

The BKN-PMFT pre-multi-frequency eddy current sorter is the world-leading product of BKN. Main tests: material mixing, poor hardness, crack, uneven depth of hardened layer, secondary tempering, surfac...

LEARN MORE >

BKN welded pipe eddy current testing machine is used for inline and offline inspection of high-frequency electrical resistance welded steel pipes. It has a high sensitivity to welding defects such as ...

LEARN MORE >1) The eddy current testing machine has high detection sensitivity for the surface and near-surface defects of conductive materials;

2) A wide range of applications can be monitored for various physical and technological factors affecting eddy current testing;

3) The eddy current machine for sale can easily achieve high-speed, high-efficiency, and automatic detection of tubes, rods, and wires without the need for a coupling agent;

4) Under certain conditions, the eddy current testing equipment can reflect information about the crack depth;

5) Monitoring can be carried out in the case where other detection methods such as high temperature, thin-walled tubes, thin wires, and inner surface of the parts are not applicable.

Eddy current testing of tubes, bars and wires including BKNET-999/H Copper Tube Eddy Current Flaw Detector, GSET-551steel wire eddy current testing, BKNET-101 Automatic Eddy Current Flaw Detector, Rod Tube Rotary Eddy Current Flaw Detector ET-R-15/40/65/90, BKNET-01\02 Welded Pipe Eddy Current Flaw Detector, LGET-553 Aluminum Tube Eddy Current Flaw Detector.

These equipments are mainly applicable to the surface defect detection of ferromagnetic non-ferrous metals, austenite, stainless steel tubes, rods and discs. It can be widely used for on-line or off-line NDT non-destructive testing of raw materials in energy, petrochemical, bearing, automobile, transom manufacturing, household appliances and other industries, such as bearings, raw materials of high strength bolts, copper, aluminum tubes of various refrigeration equipment, condenser tubes of evaporators, etc. This system is the necessary testing equipment for pipe and bar and wire production and application factory. This system adopts rotating balance point probe, resolver signal coupling, synchronously adjusting double detection probe, and the detection method of workpiece passing straight line. It has the characteristics of stable and reliable performance, high detection sensitivity, fast detection speed, no need for magnetizing and demagnetizing devices, and is sensitive to defect detection of pipe, bar and wire. It can make 100% NDT non-destructive detection of raw material surface. The equipment has the functions of defect alarm, automatic feeding and unloading and automatic sorting to achieve the detection automation. It provides an effective detection means for mass production of application pipes, rods and wires in factories and enterprises to ensure quality.

As one of the leading eddy current testing machine manufacturers in China, BKN offers eddy current machines for sale, which have high detection sensitivity and are available for a wide range of applications. We are committed to developing and manufacturing high-quality and high-performance eddy current NDT equipment to provide our customers with the best quality service.

Leave us Message: