Tapered roller bearings are separate bearings, and the inner and outer rings of the bearing have tapered raceways. This type of bearing is divided into different structural types such as a single row, double row and four-row tapered roller bearings according to the number of rows of rollers installed. Single row tapered roller bearings can withstand radial loads and axial loads in a single direction. When the bearing is subjected to a radial load, an axial component will be generated, so that another bearing that can withstand the axial force in the opposite direction is needed to balance. A tapered roller bearing is a radial thrust type rolling bearing in which the rolling elements are tapered rollers.

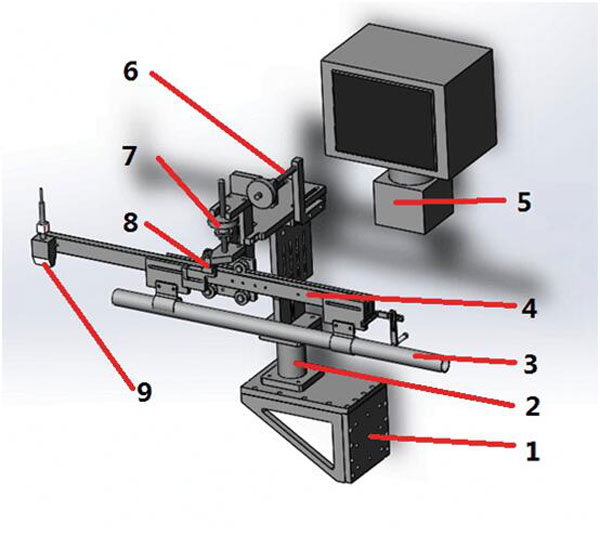

1: fixed frame 2: support frame 3: blanking pipe 4: left and right adjusting rods 5: eddy current flaw detector 6: front and rear fine-tuning 7: up and down fine-tuning 8: anti-collision device 9: eddy current probe

Test beat | Large roller,60second/min;medium roller,120second/min; Small roller,180 capsules /min |

Detection speed | 1~3piece/sec |

Frequency range | 10Hz~10MHz |

Gain | 0~99dB,step size 0.1dB |

Advanced filtering | have |

High pass | 0.1Hz~650Hz |

Low pass | 1Hz~10000Hz |

Phase rotation | 0-360 °step 1 ° |

Flaw detection accuracy | Crack length*width*depth(3*0.01*0.05)mm |

Synchronized output controlled by an internal and external clock |

High precision end and end-to-tail signal removal |

High precision real-time, delayed alarm output |

Fast digital/analog electronic balance |

Memory track delay blanking function |

Real-time impedance plane display |

The instrument can match any probe |

Remote automatic help system |

Chinese and English man-machine interface |

Non-equal amplitude-phase/amplitude alarm domain |

Computer full digital parameter adjustment |

Automatic statistics of total, number of detective products, number of qualified |

Leave us Message: