Magnetic flux leakage detection (MFL) means that after the ferromagnetic material is magnetized, a leakage magnetic field is formed on the inner and outer surfaces due to defects of the iron pipe. One can detect defects by detecting changes in the leakage magnetic field.

Welded steel pipe, also called welded pipe, is a steel pipe made by welding and forming a steel plate or strip steel. It is usually 6 meters long. The welded steel pipe has a simple production process, high production efficiency, many varieties and specifications, and low equipment investment, but the general strength is lower than that of a seamless steel pipe.

Since the 1930s, with the rapid development of high-quality strip, continuous rolling production and the advancement of welding and inspection technology, the quality of welded joints has been continuously improved, the variety specifications of welded steel pipes have been increasing, and more and more fields have replaced Seam steel pipe. Welded steel pipes are divided into straight welded pipes and spiral welded pipes in the form of welds. Classified according to production methods: process classification - arc welded pipe, electric resistance welded pipe, (high frequency, low frequency) gas welded pipe, furnace welded pipe.

Small-diameter welded pipe adopts straight seam welding, large-diameter welded pipe adopts spiral welding; according to the shape of the end of steel pipe, it is divided into round welded pipe and special-shaped (square, rectangular, etc.) welded pipe; it is divided into mining fluid according to material and use. Conveying welded steel pipes, galvanized welded steel pipes for low-pressure fluid transportation, and belt-welded steel pipes for belt conveyors. According to the specification table in the current national standard, the outer diameter* wall thickness is sorted from small to large.

Among the defective materials, some of the magnetic flux will leak to the surface of the material, and it will re-enter the material by the air, and the magnetic flux will form a magnetic flux leakage.

Magnetic flux leakage detection (MFL) means that after the ferromagnetic material is magnetized, a magnetic flux leakage field is formed on the inner and outer surfaces due to defects of the iron pipe. One can detect defects by detecting changes in the magnetic flux leakage field.

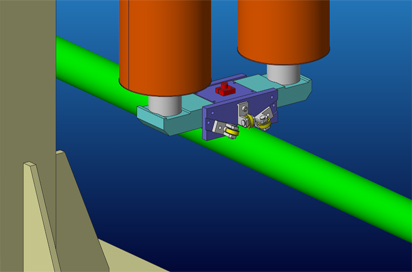

The artificial defect correction sample tube | Internal and external burrs are removed too shallow and weld seams are welded |

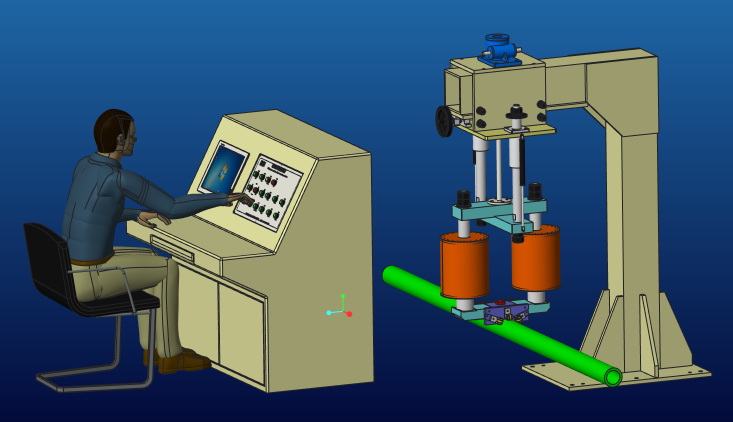

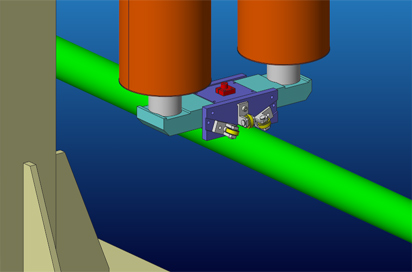

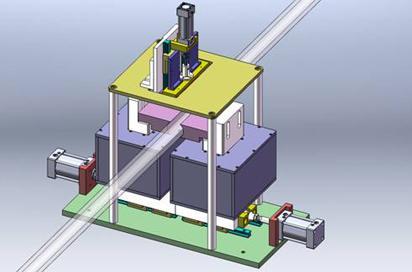

BKNMFL-02CH two-channel magnetic flux leakage inspection system

The two-channel instrument is used to drive coils and Hall elements to detect holes, inclusions, cracks, missed welds, and long-distance open pipes of welded steel pipes, especially for non-fusion welding. When defective products are produced, it will timely report the alarm, output the bad alarm signal and mark, and defective products sorting signals are sent to the sawing control system of the unit.

Ambient temperature | -10℃~40℃ |

Ambient temperature | 10%~85% |

Probe form | Differential coil or magnetoresistive element |

Gain | 99dB continuously adjustable |

Detection channel | 2 |

High pass | 1Hz~2000Hz step1Hz |

Low pass | 1Hz~2000Hz step1Hz |

inhibition | 0%~100% |

Warning level | 1%~100% |

Scrap level | 1%~100% |

Detection speed | 0~300m/min |

Blind zone setting | 1~10000ms |

Power supply | AC220V 250W adjustable |

Ambient temperature | -10℃~40℃ |

Leave us Message: