Testing Standard:GB/T 11260-2008 round steel eddy current testing method, GB/T 7735-2004 steel tube eddy

Current testing method

Longitudinal artificial injury:0.10(depth)×0.10(width)×20mm(length)

Tube end conditions:

deburring at both ends, cross-sectional deformation equal to less than the diameter tolerance

Straightness tolerance: tangential direction up to 1.5mm/m and not exceeding the total length of the workpiece

Diameter tolerance and ovality: reference DIN standard

(1)The eddy current flaw detector can accurately, reliably and stably record, alarm and mark the defects of the finished steel pipe.

(2)Detection speed:<60m/min

(3)Detection of end -end tail dead zone:

50mm signal to noise ratio: ≥ 10dB

Sample miss rate: 0%

Sample stick false positive rate: ≤2%

Stability: ≤1dB after 2 hours

Marking accuracy: ±30mm

Poor circumferential sensitivity: ≤1dB

(4)100% coverage detection, the instrument sets the upper and lower boundaries, exceeding or lower than the automatic alarm record;

(5)Flaw detection machine operation mode: fully automatic, complete electronic control system, testing equipment, auxiliary control.

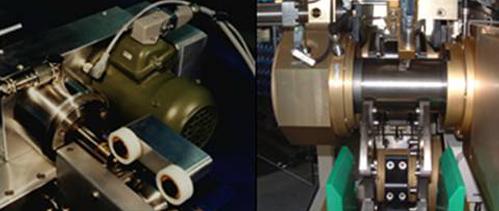

Precision positioning and drive mechanism technology in tube rod inspection;

Adopting the rotation of the probe and straight forward of the tube rod, the speed is fast, the noise is small, reliable, and the sensitivity is high;

Multi-channel noise suppression technology;

Detecting steel rods of different diameters without changing the probe, can continuously and accurately adjust the gap between the steel rod and the eddy current probe;

The signal adopts high-speed DSP signal processing mode, and each channel signal is processed independently, and the transmitted signal-to-noise ratio is high;

Wireless transmission technology, no sparks:

Has a high service life and a small longitude detection blind zone;

Do not replace the probe rotation detection technology;

The equipment can operate stably all year-round.

Leave us Message: